Aluminum rubber seals, also known as aluminum rubber gaskets or aluminum rubber grommets, are sealing components that combine the properties of aluminum and rubber to create effective seals in various applications. These seals are designed to provide a secure and durable sealing solution while also benefiting from the characteristics of both materials. Here’s more information about aluminum rubber seals:

Key Features:

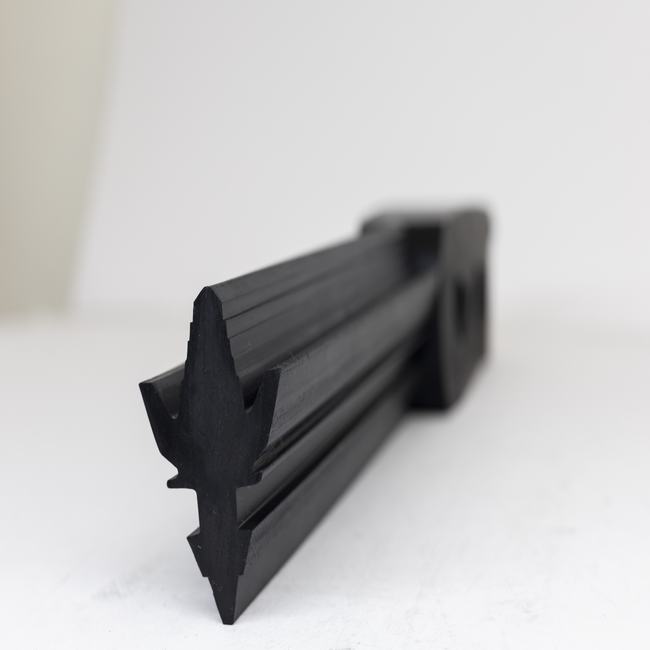

- Material Combination: Aluminum rubber seals are typically composed of an aluminum outer shell or frame and a rubber or elastomeric inner component. This combination allows them to offer the benefits of both materials.

- Durability: Aluminum provides strength and rigidity to the seal, making it more durable and resistant to deformation or damage, especially in applications with mechanical stress.

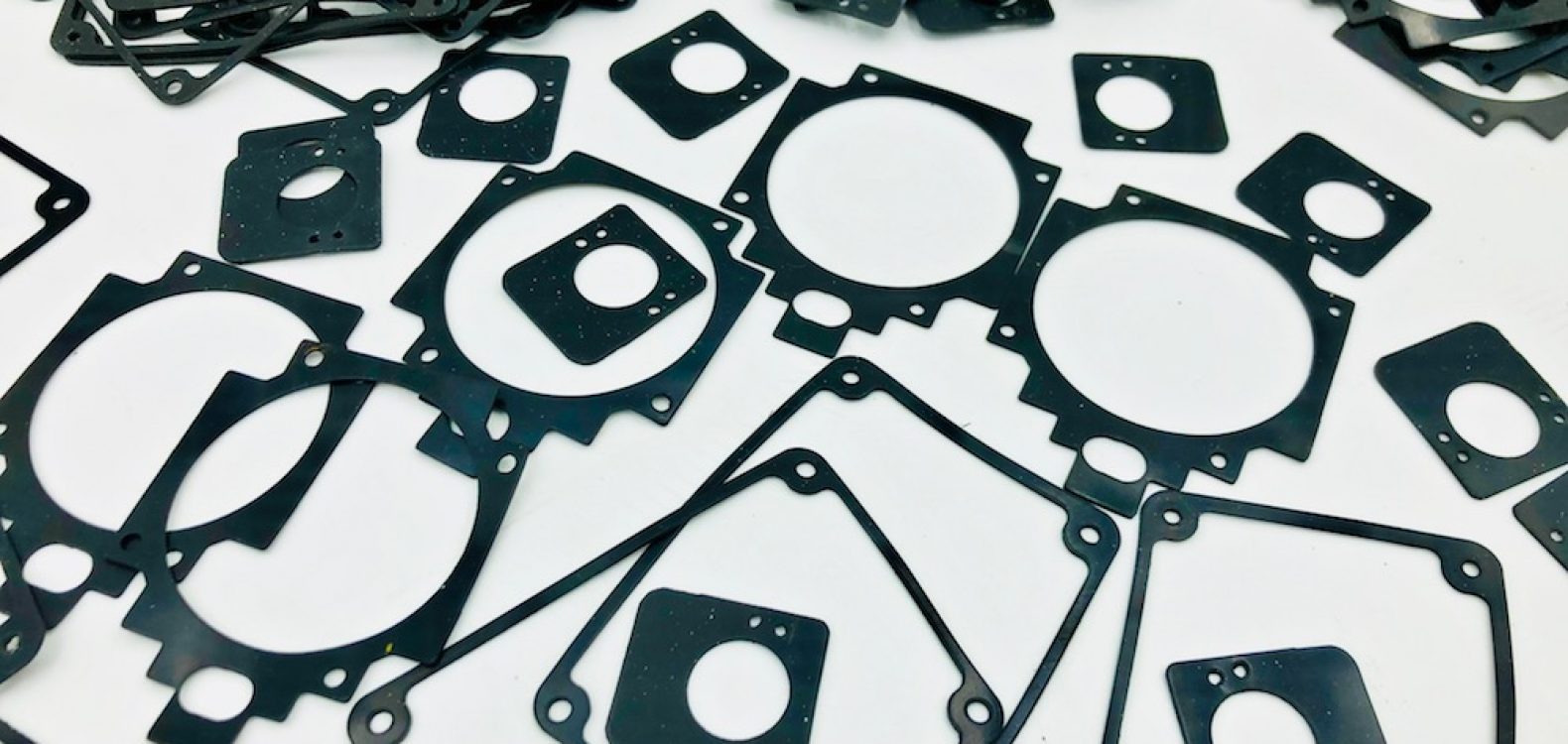

- Sealing Effectiveness: The rubber or elastomeric inner component of the seal ensures a reliable and flexible sealing function. It conforms to irregularities in mating surfaces, providing an effective barrier against fluids, gases, dust, or other environmental factors.

- Corrosion Resistance: The aluminum component of the seal offers corrosion resistance, which can be especially important in applications where exposure to harsh or corrosive environments is a concern.

- Heat and Cold Resistance: Aluminum rubber seals can handle a wide range of temperatures, making them suitable for both high-temperature and low-temperature applications.

- Customization: These seals can be customized in terms of shape, size, and design to fit specific applications and meet sealing requirements precisely.

Applications:

- Automotive Industry: Aluminum rubber seals are used in various automotive applications, including engine components, transmission systems, doors, windows, and more. They provide sealing against moisture, dust, and noise.

- Aerospace: In aerospace applications, aluminum rubber seals are used in aircraft components and systems, providing reliable sealing in critical environments.

- Electronics: They are used in electronic enclosures and connectors to ensure environmental protection and electromagnetic interference (EMI) shielding.

- Industrial Machinery: These seals are applied in industrial machinery to prevent leaks and contamination in hydraulic systems, pumps, valves, and other equipment.

- Construction: In construction, aluminum rubber seals are used in doors, windows, curtain walls, and building facades to provide weatherproofing and insulation.

- Medical Equipment: They are utilized in medical devices and equipment to ensure airtight and moisture-resistant seals.

- Consumer Goods: Aluminum rubber seals can be found in various consumer products, such as household appliances, outdoor equipment, and more.

Aluminum rubber seals are versatile components that find application across multiple industries due to their ability to provide effective sealing while offering durability and resistance to environmental factors. Properly designed and installed, these seals can contribute to the reliability and performance of various products and systems.