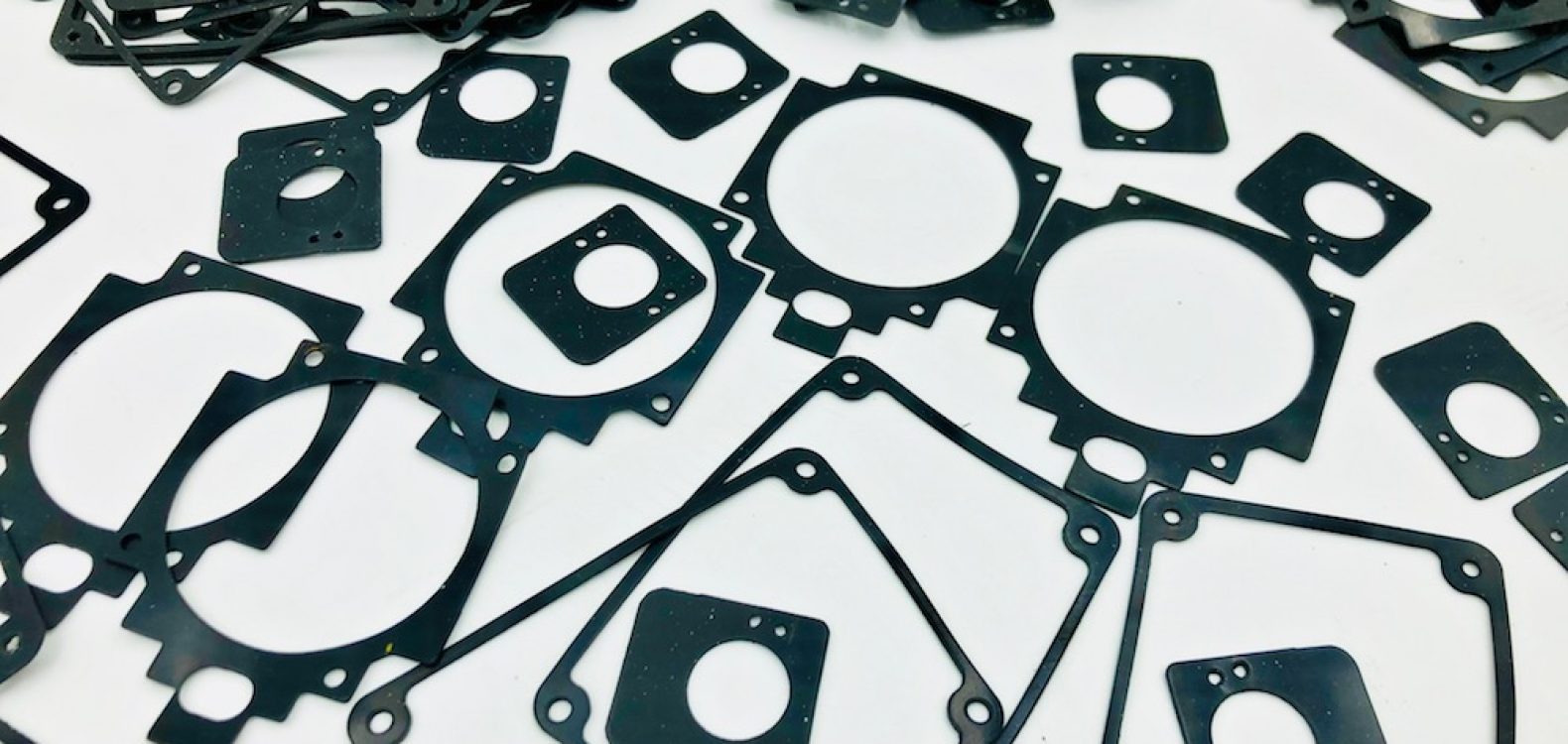

EPDM rubber seals and gaskets factory:

Factory Overview: Our state-of-the-art EPDM Rubber Seals and Gaskets Factory is a hub of innovation and excellence in the rubber manufacturing industry. Strategically located, our facility is equipped with cutting-edge technology and staffed by a team of highly skilled professionals, making us a trusted leader in producing top-quality EPDM rubber seals and gaskets.

Manufacturing Process: Our manufacturing process begins with the careful selection of high-grade EPDM raw materials. These materials undergo meticulous inspection and testing to ensure they meet our stringent quality standards. Once approved, the materials are processed using precision machinery.

- Material Preparation: The EPDM compounds are mixed and formulated to achieve the desired physical properties, including hardness, flexibility, and resistance to environmental factors.

- Extrusion and Molding: Our advanced extrusion and molding machines shape the EPDM compounds into various profiles and sizes, ranging from simple gaskets to complex seals tailored to our customers’ specifications.

- Vulcanization: The molded EPDM components are then subjected to vulcanization, a heat and chemical treatment process that enhances their durability, weather resistance, and mechanical properties.

- Quality Control: At every stage of production, our dedicated quality control team conducts rigorous inspections and tests to ensure that each EPDM rubber seal and gasket meets our exacting standards for performance and reliability.

Customization: We understand that every customer’s requirements are unique. That’s why we offer a wide range of customization options, including:

- Custom shapes and sizes to fit specific applications.

- Color options to match branding or coding needs.

- Various hardness levels to meet different sealing requirements.

- Specialized compounds for extreme environments or chemical resistance.

Quality Assurance: Quality is the cornerstone of our manufacturing process. We adhere to industry best practices and international standards to ensure the highest quality EPDM rubber seals and gaskets. Our commitment to excellence is reflected in every product that leaves our facility.

Environmental Responsibility: We are dedicated to environmental sustainability. Our manufacturing processes are designed to minimize waste and emissions, and we source our raw materials responsibly, with a focus on eco-friendly options whenever possible.

Logistics and Delivery: Our strategically located factory allows us to efficiently serve customers worldwide. We maintain a streamlined logistics system to ensure on-time delivery, whether it’s a small batch order or a large-scale production run.

Customer Support: Our customer support team is available to assist with technical inquiries, product selection, and any other customer needs. We are committed to providing exceptional service throughout the entire customer journey.

In conclusion, our EPDM Rubber Seals and Gaskets Factory is a symbol of excellence in the rubber manufacturing industry. With a dedication to quality, customization, and environmental responsibility, we deliver top-tier EPDM rubber solutions to customers across diverse industries, meeting their sealing and gasket needs with precision and reliability.