Dilatation seals, also known as expansion joints or expansion seals, are specialized engineering components designed to accommodate the expansion and contraction of various structures, including buildings, bridges, pipelines, and industrial equipment. These seals are essential for mitigating the potentially damaging effects of temperature fluctuations, seismic activity, structural settlement, and other factors that can induce movement in structures.

Here’s a comprehensive description of dilatation seals:

- Purpose: Dilatation seals are primarily employed to absorb and manage dimensional changes in a structure, which can be caused by thermal variations, seismic movements, settlement, or other dynamic forces. These changes may lead to stress, cracking, or damage in the absence of appropriate expansion and contraction accommodation.

- Types of Dilatation Seals:

- Thermal Expansion Joints: These seals are designed to address the expansion and contraction resulting from temperature fluctuations. They are commonly used in structures such as buildings and bridges.

- Seismic Expansion Joints: Specifically engineered to absorb movements during seismic events, helping to prevent structural damage in earthquake-prone regions.

- Bridge Expansion Joints: Found in bridges and overpasses, these joints accommodate movements due to traffic loads, temperature changes, and seismic activity.

- Piping Expansion Joints: Used in industrial applications to handle thermal expansion and contraction of pipelines, preventing stress and damage to the system.

- Architectural Expansion Joints: These are used in buildings to maintain the aesthetic appearance and structural integrity while allowing for movement.

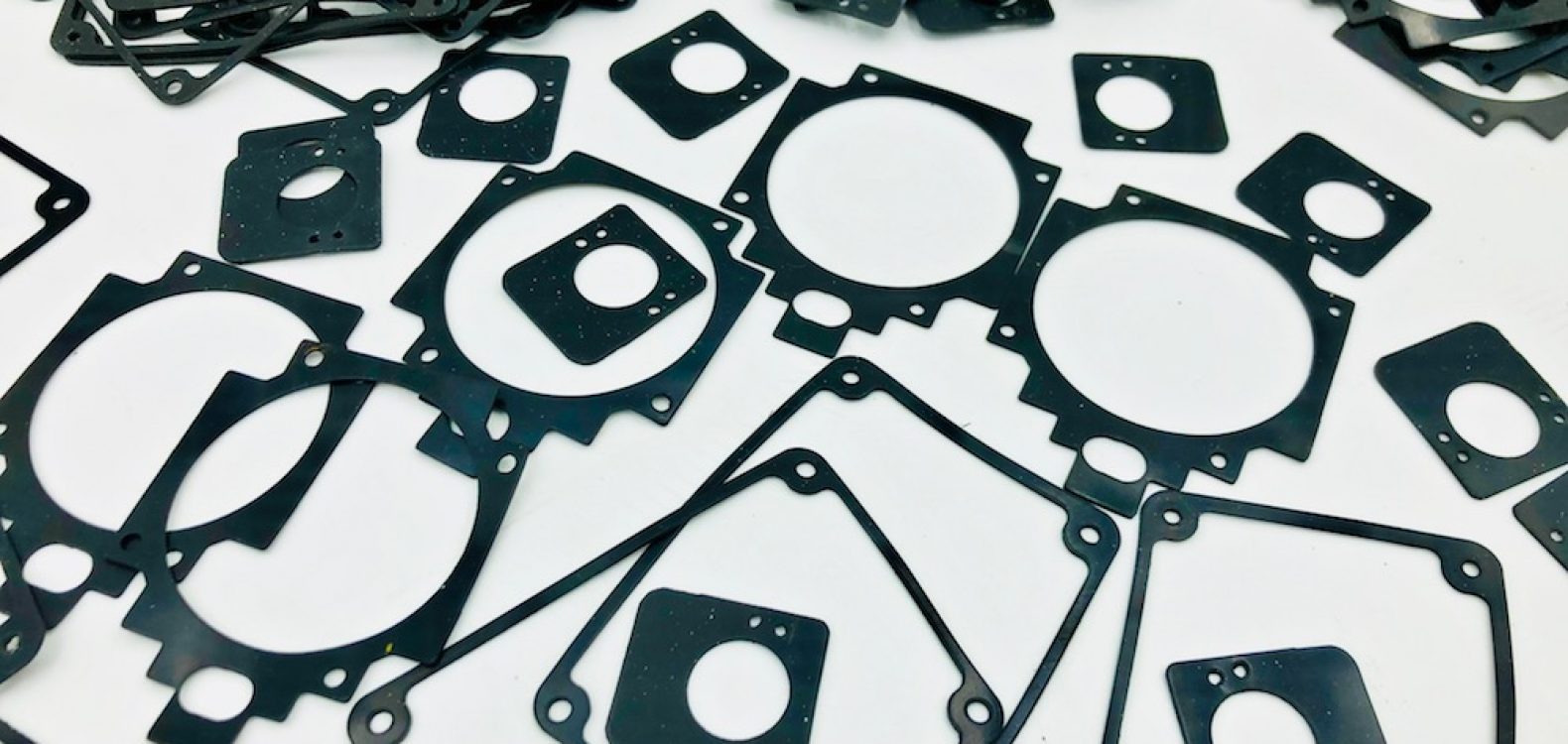

- Materials:

- Dilatation seals can be constructed from various materials, including rubber, elastomers, metal, and composite materials, depending on the specific application and requirements.

- Design and Construction:

- Dilatation seals are designed to be flexible and capable of stretching, compressing, or pivoting to accommodate movements.

- They are often installed at predefined locations within a structure where movement is expected, such as between different sections of a bridge or along the perimeter of a building.

- The design must take into account factors such as the expected range of movement, load-bearing capacity, environmental conditions, and durability.

- Function:

- When a structure expands, the dilatation seal compresses to maintain a tight seal and prevent the entry of moisture, debris, or other contaminants.

- When a structure contracts, the seal expands to prevent gaps from forming, which could lead to leaks, cracks, or structural damage.

- Maintenance:

- Regular inspection and maintenance are essential to ensure the continued effectiveness of dilatation seals. This may include checking for wear and tear, replacing damaged seals, and cleaning to prevent clogging.

- Importance:

- Dilatation seals are critical for the long-term structural integrity and safety of buildings, bridges, and infrastructure.

- They help prevent damage, improve energy efficiency, and reduce maintenance costs over time.

- Applications:

- Dilatation seals are used in a wide range of industries, including construction, transportation, industrial processing, and infrastructure development.

In summary, dilatation seals are crucial components in modern engineering and construction, providing a means to manage structural movements and maintain the integrity of various structures. Their design, material selection, and proper installation are essential for ensuring the long-term functionality and safety of the built environment.