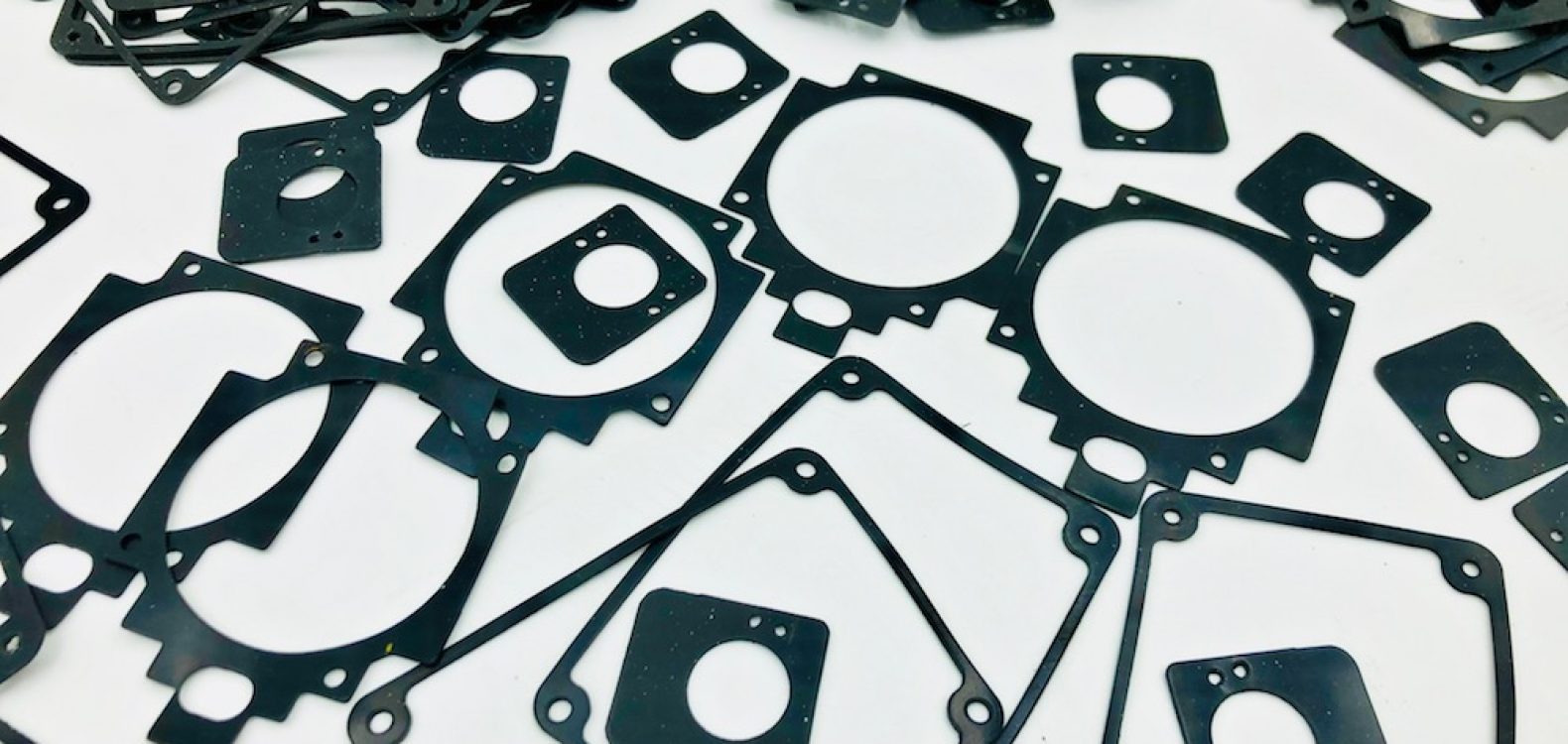

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are widely used sealing components known for their excellent weather resistance, heat resistance, and durability. These gaskets are employed in various industries and applications where a reliable and long-lasting seal is required. Here’s more information about EPDM rubber gaskets:

Key Features:

- Weather Resistance: EPDM rubber is highly resistant to outdoor weather conditions, including UV radiation, ozone, and extreme temperatures. This makes EPDM gaskets suitable for outdoor and exposed applications.

- Temperature Tolerance: EPDM rubber gaskets can withstand a wide range of temperatures, from -40°C to 125°C (-40°F to 257°F), making them suitable for both cold and hot environments.

- Chemical Resistance: EPDM rubber exhibits resistance to a variety of chemicals, including acids, alkalis, and polar solvents, making it versatile for use in different industrial settings.

- UV Resistance: EPDM gaskets are resistant to ultraviolet (UV) radiation, making them ideal for outdoor applications that are exposed to sunlight.

- Durability: EPDM rubber is known for its long service life, even in challenging environments. It can maintain its properties over an extended period.

- Flexibility: EPDM gaskets are flexible and conformable, allowing them to seal effectively on irregular surfaces and adapt to various shapes.

- Water Resistance: EPDM is inherently water-resistant and provides a reliable seal against moisture and water ingress.

Applications:

- Automotive Industry: EPDM rubber gaskets are used in vehicles for sealing applications, including door seals, window seals, and gaskets for engine components.

- Construction: In the construction industry, EPDM gaskets are employed in roofing systems, curtain wall systems, and window seals to ensure weatherproofing and insulation.

- HVAC Systems: EPDM rubber gaskets are used in heating, ventilation, and air conditioning (HVAC) systems to create airtight seals in ductwork and components.

- Electrical Enclosures: They are used in electrical enclosures to provide a weatherproof seal and protect electrical components from moisture and dust.

- Plumbing and Piping: EPDM gaskets are utilized in plumbing systems, pipes, and fittings to create watertight seals in applications such as water distribution and wastewater systems.

- Industrial Equipment: EPDM rubber gaskets are used in various industrial equipment and machinery to seal joints, connections, and enclosures.

- Marine Applications: EPDM gaskets are suitable for marine environments, including boat hatches, ports, and other marine sealing applications.

- Food and Beverage Industry: EPDM gaskets meet FDA (Food and Drug Administration) standards and are used in food and beverage processing equipment.

- Pharmaceutical Industry: EPDM gaskets are used in pharmaceutical manufacturing for sealing and containment purposes.

EPDM rubber gaskets are versatile and widely accepted in many industries due to their excellent sealing properties and durability. They play a critical role in ensuring the integrity of various systems and components while providing resistance to environmental factors and chemicals. Proper selection and installation are essential to maximize the performance of EPDM gaskets in specific applications.