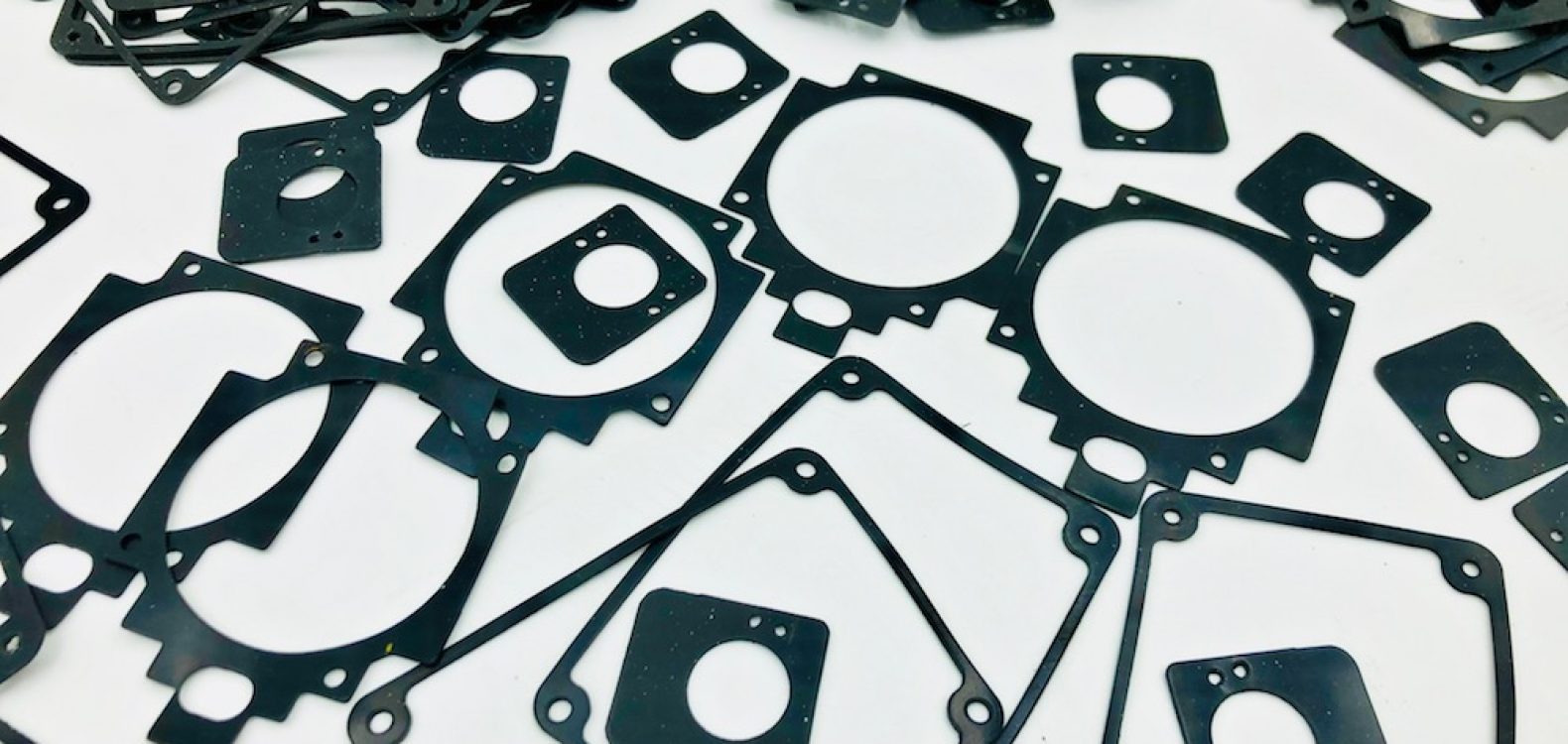

EPDM rubber seals and gaskets are widely used in various industries due to their excellent properties. Here’s an overview:

- Weather Resistance: EPDM rubber is known for its outstanding resistance to weathering, ozone, and UV exposure. This makes it suitable for outdoor applications where exposure to sunlight and harsh weather conditions is common.

- Temperature Resistance: EPDM gaskets exhibits good resistance to high and low temperatures, making it suitable for use in a wide range of temperature environments. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F) without losing its flexibility or mechanical properties.

- Chemical Resistance: EPDM rubber has good resistance to many chemicals, acids, and alkalis. It is resistant to polar substances like ketones, alcohols, and glycols, but it is not recommended for use with oils, petroleum-based fluids, or fuels.

- Water Resistance: EPDM rubber has excellent water resistance properties, making it suitable for sealing applications where exposure to water or moisture is expected.

- Flexibility: EPDM rubber is highly flexible and can maintain its elasticity over a wide range of temperatures. This flexibility allows it to conform to irregular shapes and provide effective sealing.

- Electrical Insulation: EPDM rubber has good electrical insulating properties, making it suitable for use in electrical enclosures and applications where electrical insulation is required.

- Tear and Abrasion Resistance: EPDM rubber has good tear and abrasion resistance, which ensures durability and long service life in demanding applications.

EPDM rubber seals and gaskets find applications in various industries such as automotive, construction, HVAC (Heating, Ventilation, and Air Conditioning), aerospace, and manufacturing. They are commonly used for sealing doors, windows, automotive engine components, electrical enclosures, piping systems, and more.