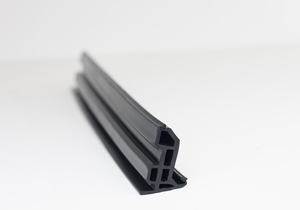

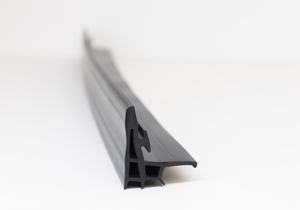

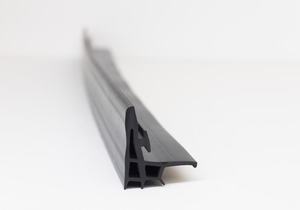

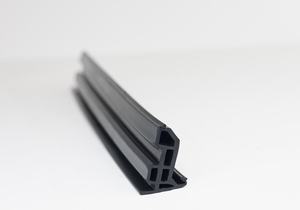

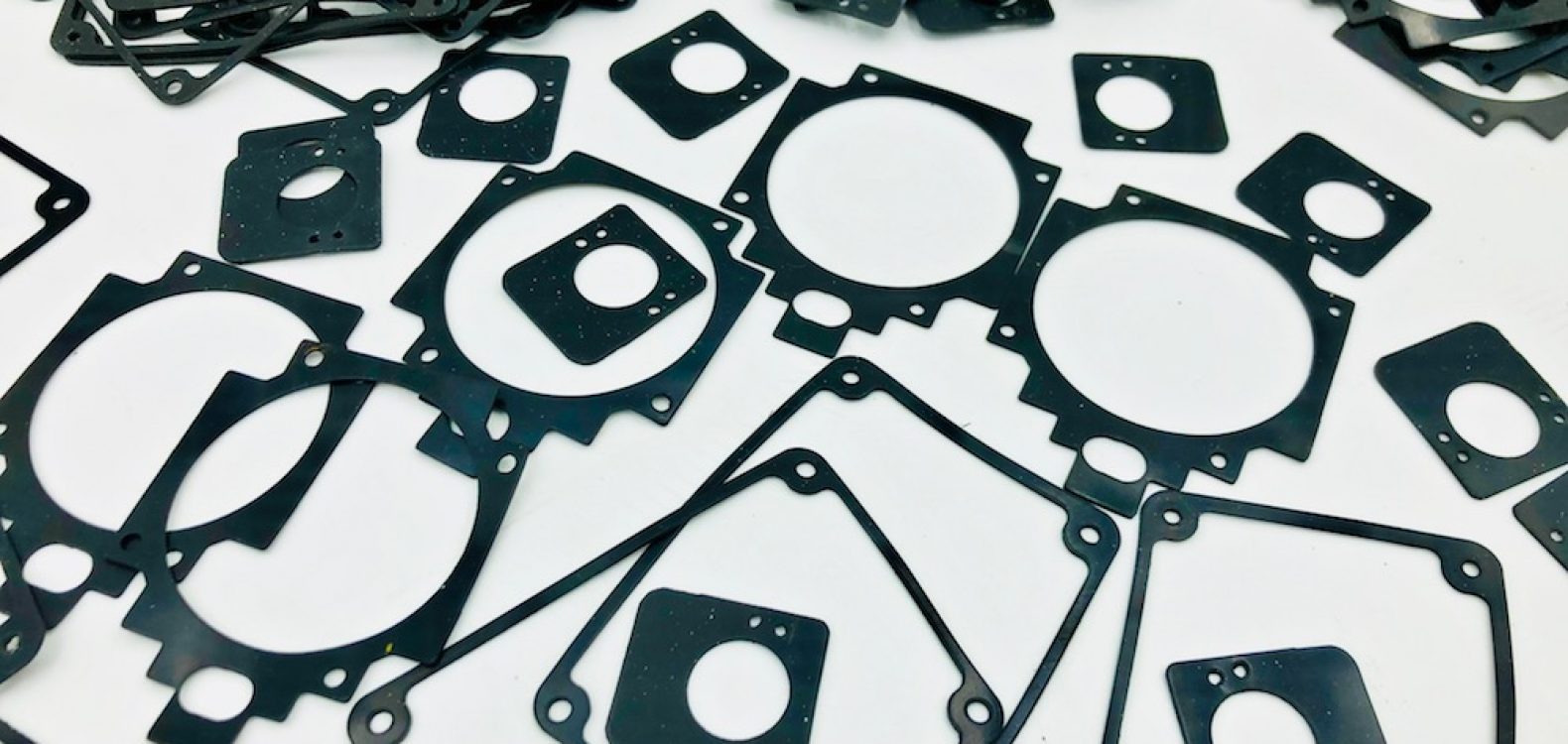

Ethylene Propylene Diene Monomer EPDM rubber seals and gaskets are versatile elastomeric materials renowned for their outstanding properties, making them indispensable in various industries and applications. Here’s a comprehensive overview of EPDM rubber seals and gaskets:

- Material Composition: EPDM is a synthetic rubber compound composed of ethylene, propylene, and a diene monomer. This unique blend imparts exceptional durability and resilience to the material.

- Weather Resistance: EPDM exhibits remarkable resistance to UV radiation, ozone, and extreme weather conditions. This makes it an ideal choice for outdoor applications, including automotive weatherstripping, roofing membranes, and outdoor sealing.

- Temperature Range: EPDM can withstand temperatures ranging from -40°C (-40°F) to 150°C (302°F) without losing its flexibility or integrity, making it suitable for both hot and cold environments.

- Chemical Resistance: EPDM resists a wide range of chemicals, acids, and alkalis, making it suitable for use in the chemical industry and as gaskets in pipelines where exposure to corrosive substances is a concern.

- Sealing Properties: EPDM rubber is known for its excellent sealing capabilities. It can maintain a reliable seal, even in low-pressure applications, preventing leaks and ingress of moisture, dust, or gases.

- Electrical Insulation: EPDM is an excellent electrical insulator, making it suitable for electrical enclosure gaskets, wire and cable insulation, and electrical connectors.

- Flexibility and Elasticity: EPDM remains flexible and elastic over time, ensuring a long service life and resistance to cracking or breaking, especially in dynamic applications.

- Low Toxicity: EPDM is a low-toxicity material, making it safe for use in applications where contact with food or potable water is possible.

- Noise and Vibration Dampening: EPDM can dampen noise and vibrations, making it useful in automotive applications such as door seals and engine mounts.

- Ease of Fabrication: EPDM can be easily molded, extruded, or cut into various shapes, making it adaptable to a wide range of applications.

- Color Options: EPDM is available in various colors, allowing for aesthetic customization and color-coding in applications.

- Regulatory Compliance: EPDM rubber often complies with industry standards and regulations, ensuring its suitability for critical applications.

- Applications: EPDM rubber seals and gaskets find use in automotive manufacturing, construction, HVAC systems, aerospace, marine, and many other industries.

In conclusion, EPDM rubber seals and gaskets offer a compelling combination of durability, flexibility, weather resistance, and chemical stability. These properties make them a preferred choice in demanding applications across multiple industries, providing reliable sealing and protection in a wide range of environments.