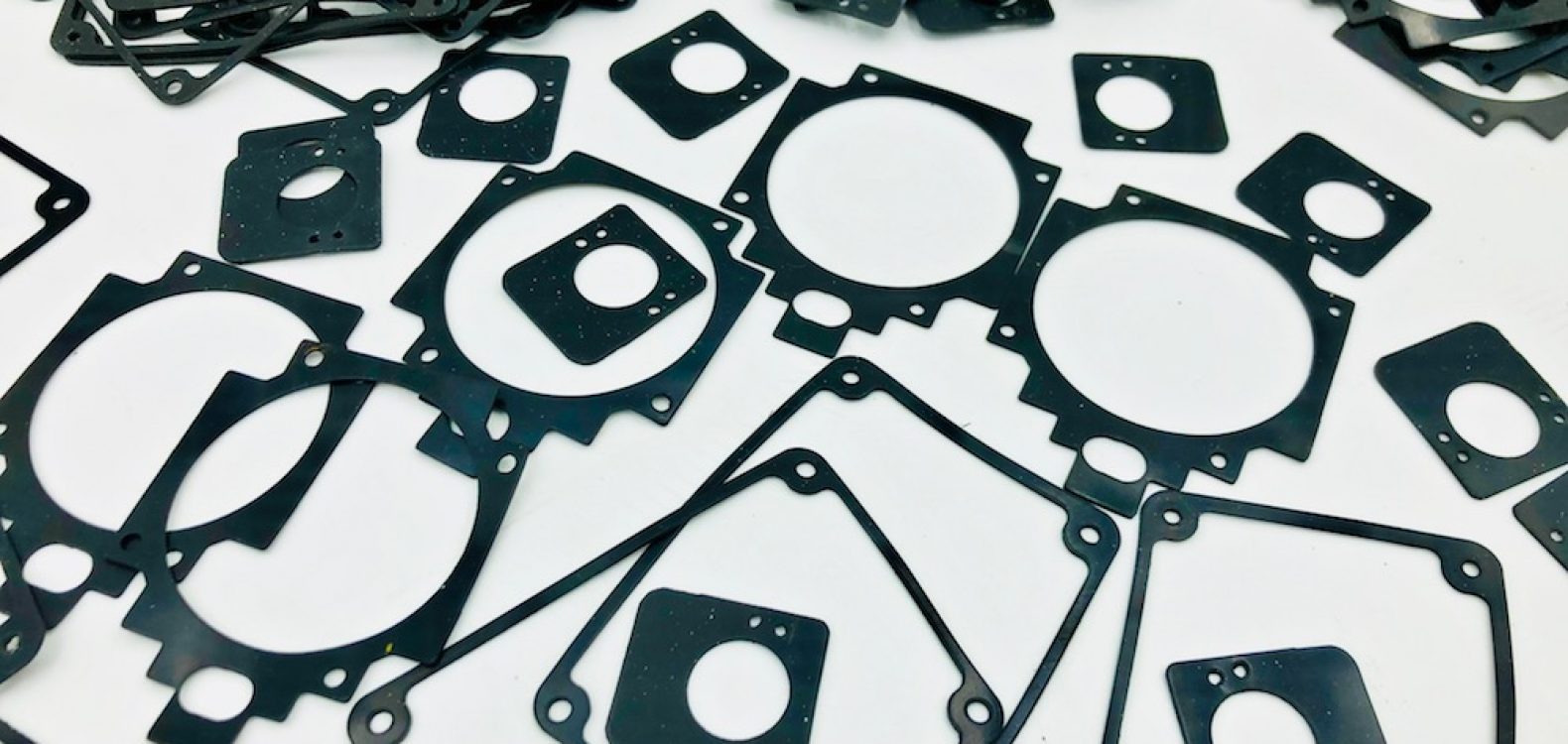

Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are essential components used in concrete pipe systems to provide watertight and secure connections between individual pipes or pipe sections. These seals play a crucial role in preventing leaks, maintaining the integrity of the sewer or drainage system, and ensuring environmental protection. Here’s more information about concrete pipe seals:

Key Features:

- Material Composition: Concrete pipe seals are typically made from elastomeric materials such as natural rubber, EPDM (Ethylene Propylene Diene Monomer), or neoprene. These materials offer flexibility and resilience, allowing the seal to conform to irregularities in the concrete pipe surfaces.

- Watertight Sealing: The primary function of concrete pipe seals is to create a watertight and airtight seal between adjoining pipes or pipe sections. This prevents the escape of sewage or wastewater and the entry of groundwater or contaminants.

- Durability: Concrete pipe seals are designed to withstand the harsh conditions of sewer and drainage systems, including exposure to chemicals, UV radiation, and temperature variations. They have a long service life and resist degradation.

- Ease of Installation: Installing concrete pipe seals is typically straightforward and does not require specialized tools or equipment. They are often designed for quick and efficient assembly.

- Chemical Resistance: These seals are resistant to a wide range of chemicals commonly found in sewage and wastewater systems, ensuring their long-term effectiveness.

Applications:

- Sewer and Drainage Systems: Concrete pipe seals are extensively used in sewer and stormwater drainage systems to create reliable and leak-free connections between concrete pipes. They help prevent sewage or stormwater leaks into the surrounding environment.

- Culverts and Bridges: In infrastructure projects like culverts and bridges, concrete pipe seals are employed to ensure proper water management and drainage.

- Municipal and Industrial Wastewater Systems: These seals are crucial in municipal wastewater treatment plants and industrial facilities to maintain the integrity of wastewater conveyance systems.

- Water Treatment Plants: Concrete pipe seals are used in water treatment facilities to manage the flow of treated water, ensuring it reaches its intended destination without leaks.

- Agricultural Drainage: In agricultural applications, concrete pipe seals are utilized in drainage systems to prevent waterlogging of fields and enhance soil health.

- Construction and Infrastructure: In construction projects, concrete pipe seals are commonly used for various water management and drainage purposes, including under roadways and highways.

- Trenchless Pipe Rehabilitation: When rehabilitating or repairing underground concrete pipes using trenchless methods, new concrete pipe seals may be installed to ensure a reliable connection between old and new pipe sections.

Properly selected and installed concrete pipe seals are essential for the effectiveness and longevity of concrete pipe systems. They contribute to environmental protection, prevent infrastructure damage, and ensure the reliable conveyance of fluids in sewer, drainage, and water management applications.